The core of brand space is to convey values, but the uniform texture and inability to customize colors of traditional stone make design a 'production line product'. How to make the wall truly become the carrier of brand stories

Justone SMT stone redefines stone engineering standards with "industrial precision+flexible adaptation":

one ️⃣ Zero error logic from drawings to reality

Professional laboratory updates and iterates 3D spray coating technology to ensure that the size and presentation of each patch are 100% matched with the buyer's required stone style

two ️⃣ The 'foolproof' installation of complex structures

Curved walls, spiral columns, and other irregular base materials? Flexible material+exclusive adhesive, directly bonded without cutting, reducing construction time by 40%.

three ️⃣ Full chain quality control

From sampling to delivery, the color palette and production batch data are retained throughout the entire process to prevent disputes over "goods not matching the board".

Data endorsement:

7-day rapid prototyping: After confirming the effect, the 2000 square meter order will be delivered within 15 days (traditional craftsmanship requires 45 days+).

Cost reduction of 25%: eliminates the need for dry hanging steel frames and mortar leveling, resulting in lower overall costs.

Engineering case:

Renovation of shopping center facade: 20000 square meters of curved stone installation completed within 30 days, with zero rework acceptance.

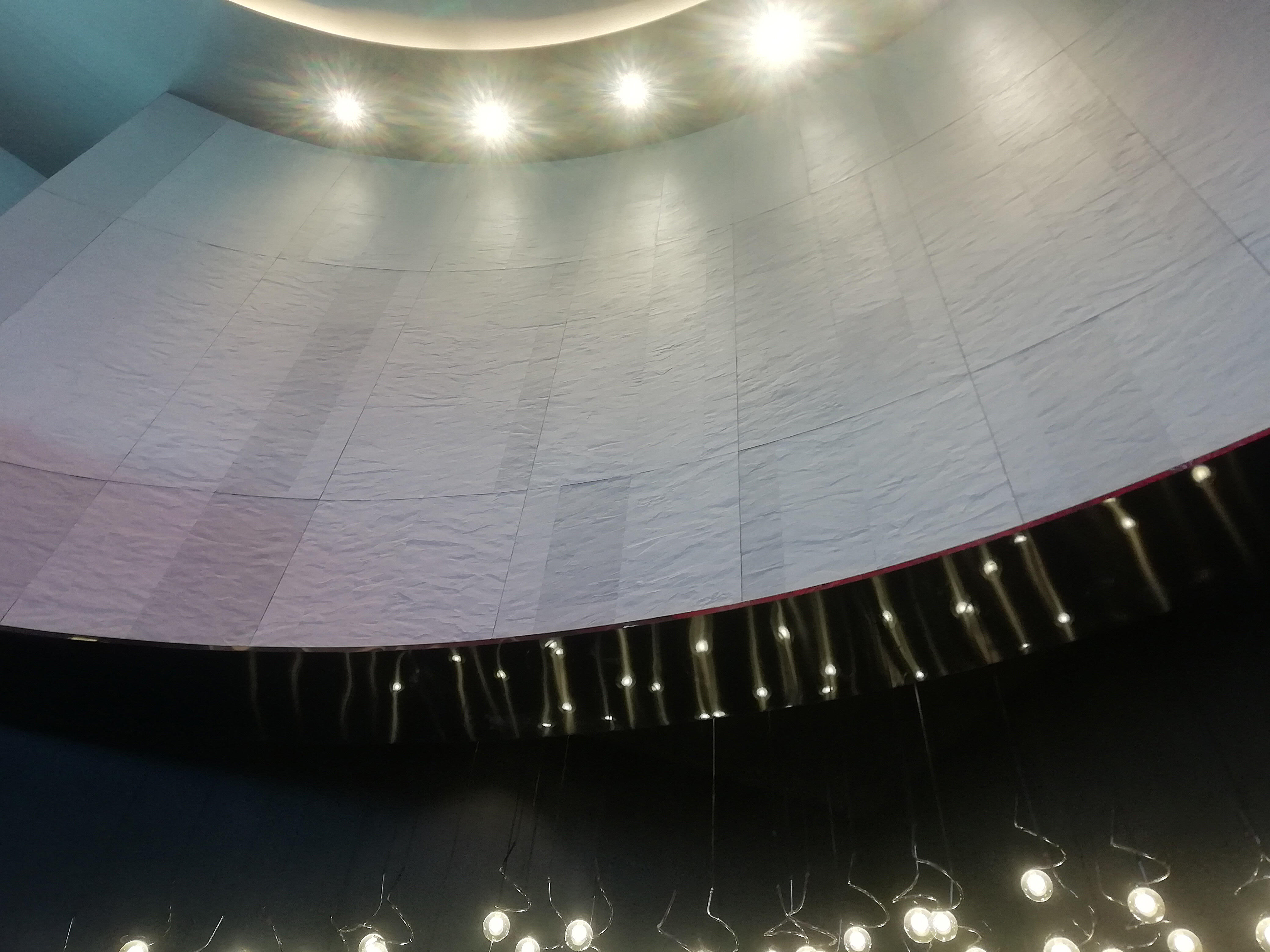

Hotel banquet hall dome: 28 days delivery without seam error.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

ID

ID

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

MS

MS

GA

GA